What is fiberglass?

Glass fiber - finishing material for walls, consisting of impregnated fiberglass. The surface has a relief pattern. Glass cloth wallpapers are made from glass blanks that melt under high temperature and stretch the fibers. Threads are subsequently created from them, and then cloth or fiberglass by weaving. Later, the surface is treated with an impregnation for the stability of the material.

Structure

Glass cloth wallpaper consists of natural materials: soda, clay, limestone, quartz sand. For transformation from blanks into fiberglass, only a high temperature, reaching 1200 degrees, is required. The impregnation, which is applied at the end of the work for the durability of the material, is based on modified starch.

Specifications

| Name | Value |

|---|---|

| Life time | more than 30 years |

| Possibility of staining | Staining up to 20 times |

| Standard size, (m.) | 1x25; 1x50 |

| Static electricity | Does not accumulate |

| Water vapor permeability | High |

| Fire-fighting properties | there is |

| Minimum density of wallpaper for wall decoration | 100 g / sq. m. |

Types of fiberglass wallpaper

By invoice

Glass fiber has two main types of texture, smooth and embossed. Different types of wallpapers can fulfill different functions.

Smooth

Smooth fiberglass wallpaper is otherwise called cobweb or glass non-woven. This is due to visual similarities. In addition to the aesthetic function, smooth glass wallpaper also performs a practical one, namely, it is used to strengthen and level walls or ceilings. Smooth glass wallpaper will be a good option for finishing the ceiling, the surface is smooth and even.

Embossed

Another name is traditional glass wallpaper. Material with a higher density compared to smooth wallpaper. The surface has a clearly defined relief, forming some kind of ornament or pattern. This type of fiberglass wallpaper is suitable for the final wall decoration.

Mat

The type of texture has the name of the fabric, which is distinguished by a unique and recognizable way of weaving threads; visually, the surface of the fiberglass wallpaper looks like a cloth. The weave can be small, medium and large.

Rhombus

The weaving of the fiberglass cloth forms a diamond-shaped pattern along the entire length of the cloth. The drawing can be with shapes of equal or different sizes. Rhombuses also distinguish between large, medium and small. Visually, the wall covering is similar to jacquard.

Herringbone

The glass cloth has a zigzag pattern along its entire length. Like other types, the pattern can be of different sizes.Small ornament is suitable for finishing small rooms, such as a corridor.

On order

Today, in addition to the usual patterns, fiberglass wallpaper is made with other patterns, in production you can also make an individual order for a unique weaving according to an individual sketch.

By quality

The quality of fiberglass depends on their density, the higher it is, the stronger the material and longer service life.

| 1 class | The most durable coating of this type of wallpaper. Service life on average 30 years. The density of fiberglass is more than 100 grams per square meter. The canvas is ready for repeated repainting, without loss of external qualities. |

|---|---|

| 2nd grade | The density of the fiberglass cloth is less than 100 grams per square meter. Glass fiber has a shorter service life. A good option for budget renovation. Re-painting clogs the pattern and makes the texture less visible. |

| Economy | Manufacturing defects are not uncommon. Material with low density and, accordingly, quality. |

By color

For painting

Glass cloth wallpaper for painting is made in a neutral color, most often it is white or beige. Such a background allows you to apply any shade to the surface without distorting it.

Colored

Colored glass-cloth wallpapers are not intended for painting, paint is added during production. This type of finish is suitable for premises that do not require regular renovation.

On the picture dining room in classic style. The decoration is made with glass wallpaper in orange tones.

By water resistance

When produced on rolls or packaging, the degree of water resistance of glass cloth wallpaper is indicated. The designation is in the form of waves. The more waves, the higher the water resistance of the material.

1 wave

Glass fiber is poorly in contact with water. The surface can be washed with a slightly damp soft cloth or chamois leather.

2 waves

They denote the average degree of moisture resistance of the glass cloth, the material better tolerates contact with water. The surface can be cleaned with a cloth or soft sponge and water or soapy water.

3 waves

The three-wave icon means a high degree of moisture resistance of the fiberglass. When leaving, it is allowed to use non-abrasive detergents.

Pros and cons

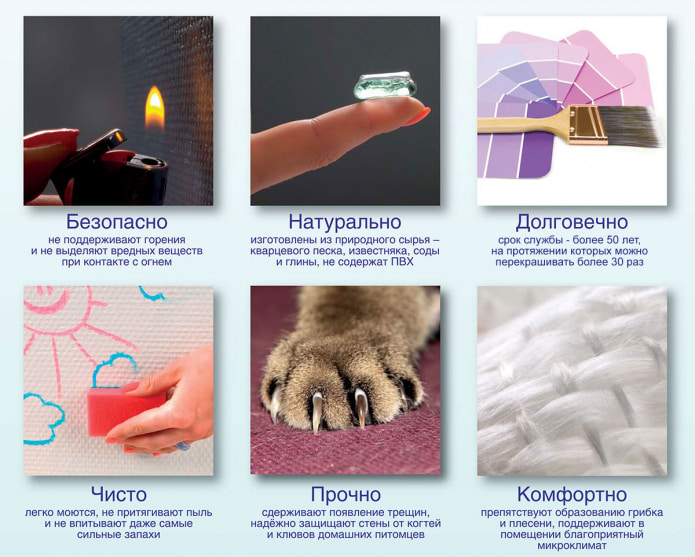

Like any material, fiberglass wallpaper has a number of advantages and disadvantages over other finishing materials. Considering all the nuances, you can easily decide on the relevance of this type of wallpaper for a particular room.

| pros | Minuses |

|---|---|

| High fire-fighting properties | High price |

| Consists of environmentally friendly materials, therefore safe for health | Only latex or acrylic paint is suitable for staining. |

| High strength of fiberglass coating, due to which the fabric has reinforcing properties | A special glue is required, the price of which is also higher than other adhesives. |

| Vandal-proof qualities | Glass cloth wallpaper is difficult to remove, since the impregnation is firmly attached to the glue. |

| Long service life | It is imperative to observe safety rules during work, namely the presence of a respirator. |

| Glass fiber is resistant to changes in humidity and temperature, as well as sunlight. | |

| Sound insulation increases | |

| The walls are breathing |

On the picture infographics about the advantages of fiberglass

How to properly glue on the walls?

Which glue to choose?

For fiberglass wallpaper, you need to use special glue, liquids for ordinary paper wallpaper will not work, they will simply be ineffective, since they will not withstand the weight of the fiberglass. Today in the building industry there is a large selection of glue designed for gluing fiberglass from a number of manufacturers, such as Oscar, Quelyd or Kleo. Their composition takes into account the features of fiberglass material, the mixture can be purchased ready-made or dry.

What surface is better for gluing?

Glass fiber must be glued to the prepared surface. To do this, it is necessary to remove the old finish and level the walls with putty, minor irregularities can not be removed. The walls are sanded and primed. After that, the surface is ready for finishing.

How long do they dry?

Glass fiber dries in average day - two... In this case, the temperature in the room should be from 10 to 25 degrees. It is also necessary to exclude the possibility of drafts or bright sunlight.

Preparing the walls

Before you start gluing the fiberglass material, you need to prepare the work surface.

- Remove old trim,

- level the surface with putty,

- seal drywall joints or small cracks with a paint net,

- sand

- prime with a roller,

- after complete drying, the walls are ready for gluing fiberglass.

Gluing technology

Before starting work, it is necessary to apply the markings and prepare the glue. The markings will help to stick the wallpaper evenly without flipping the side. For this, a line perpendicular to the ceiling is drawn, which is measured using a plumb line or level. The glue will be ready 15 minutes after mixing.

- It is necessary to adhere to safety measures, namely to wear protective glasses and gloves.

- The wallpaper starts to glue from the door. The adhesive is applied to the wall, protruding beyond the edges of the mark.

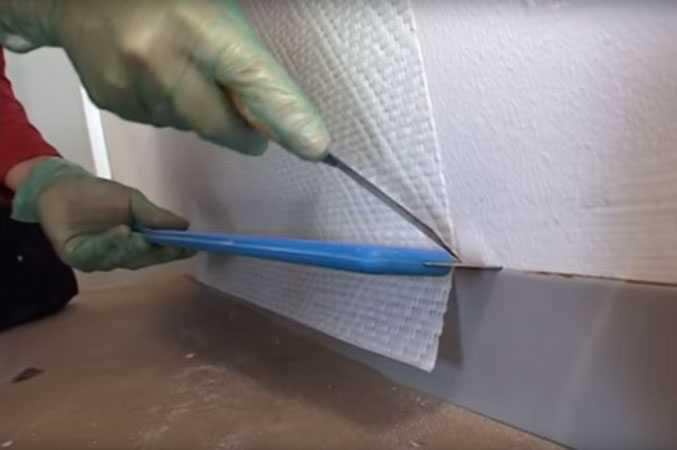

- From top to bottom, a glass fiber sheet is applied and smoothed with a plastic spatula.

- According to the same principle, the next sheet is glued end-to-end.

- Seams are pressed and smoothed last.

- After 24-48 hours, the wallpaper will dry and be ready for painting if needed.

Video

Features of use on the ceiling

The gluing of glass fiber wallpaper is carried out according to the same principle as on the walls. Self-adhesive tape will help to check the strength of the old plaster on the ceiling.

- The direction starts from the window to the opposite wall.

- The glue is used only specifically for fiberglass, the other will not support their weight.

- The glue is applied only to the ceiling.

- You need to act consistently, the next strip of glue is spread after the wallpaper sheet is glued.

- The gluing is done end-to-end, with an overlap on the walls.

- The excess is cut off after drying.

How to paint correctly?

Which paint to choose?

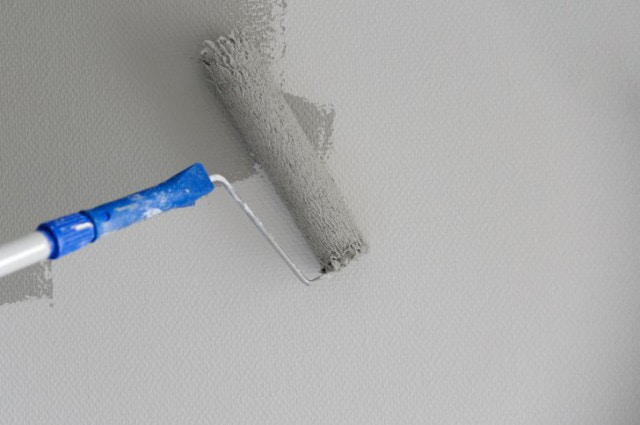

For painting glass cloth coatings, water-dispersion paint is best suited. The choice is due to the absence of toxic substances, fast drying and the absence of unpleasant odors. Depending on the type of room, you can choose acrylic, styrene-butadiene or latex paint.

Step-by-step painting instructions

Painting glass wallpaper has a simple procedure. However, strict adherence to it helps to achieve an ideal result.

- Preparing the room and tool. Cover the floor, radiators and baseboards with foil or newspaper.

- The walls are primed, after which you need to wait until it dries completely,

- the corners of the room are painted over with a brush,

- walls are painted with a roller,

- breaks should be avoided for even application. Paint applied to an already dried surface will be noticeable at the border.

- The second layer is applied after 12 hours.

Video

How to choose fiberglass?

Fiberglass wallpaper must be selected according to some criteria, namely pattern, manufacturer, class and composition.

- The higher the density of the fiberglass material, the stronger the material and the longer the service life,

- fiberglass wallpaper of lower density is not as strong, but has a low cost,

- the pattern is selected depending on personal preferences, it is also possible to make an individual order for a unique pattern,

- the more voluminous the drawing, the more times it can be covered with paint,

- the ideal composition is a ratio of 70% glass and 30% impregnation,

- the edges in the roll should be even, and the weaving should be neat.

Photo ideas in the interior

For bathroom

Glass fiber will be a good finishing option for a bathroom. They are not afraid of moisture and will not allow mold and mildew to appear.

On the picture bright bathroom. The decoration is done with turquoise glass cloth wallpaper.

For greater strength and reliability, the fiberglass cloth is covered with washable paint.

On the picture spacious bathroom with glass-cloth wallpaper in blue.

For kitchen

High fire resistance of glass fiber wallpaper can be considered a big advantage.

On the picture modern kitchen with glass wallpaper in neutral colors.

In a kitchen, this fact is very relevant. At high temperatures, fiberglass cloths do not emit harmful substances. In addition, replacement of glass fiber wallpaper will be cheaper and easier to work with. Suitable for finishing the dining area.

In the toilet

In the toilet, as well as in the bathroom, it is important to minimize the possibility of mold and mildew. Glass fiber will help with this, they will be a good alternative to tiles. In addition, their cost is lower than tiles.

In the hall

The strength of the fiberglass material will eliminate mechanical damage to the surface, and the waterproof coating is easy to care for and keep clean.

On the balcony

Fiberglass wallpapers are not afraid of temperature and humidity changes, they will become a practical solution for finishing a glazed balcony or loggia.

Tips for caring for and washing your wallpaper

The fiberglass material itself is quite durable and is able to withstand various cleaning methods. The method must be selected depending on the paint covering the surface.

- To remove stains from glass cloth surfaces, you can use non-abrasive detergents,

- depending on the moisture resistance of the paint, you can use a soft suede or a brush,

- for preventive maintenance, it is enough to remove dust with a dry soft brush.

Photo gallery

Glass fiber is a practical and at the same time beautiful method of interior decoration. High strength indicators of fiberglass material allow finishing in any room, and the safety of their composition makes it possible to decorate a nursery or a balcony without worrying about the release of harmful substances. At the same time, the material breathes and protects against mold.

10 practical tips for arranging a small kitchen in the country

10 practical tips for arranging a small kitchen in the country

12 simple ideas for a small garden that will make it visually spacious

12 simple ideas for a small garden that will make it visually spacious

13 bad habits a good housewife shouldn't have

13 bad habits a good housewife shouldn't have 24/7 home cleanliness - 4 secrets for the perfect housewife

24/7 home cleanliness - 4 secrets for the perfect housewife 6 hotels in Sochi that will give odds to the promoted foreign hotels

6 hotels in Sochi that will give odds to the promoted foreign hotels Top 10 interior design trends 2020

Top 10 interior design trends 2020 Rating of cheap TVs with Smart-TV

Rating of cheap TVs with Smart-TV New Year's LED garlands on AliExpress - we disassemble while it's hot, so that it's bright at home

New Year's LED garlands on AliExpress - we disassemble while it's hot, so that it's bright at home