Cold welding

The most popular way to process linoleum seams at home, it does not require any special skills and equipment. Its essence in that glue is applied along the line of joining the edges, which dissolves the coating for a short time. After the solvent evaporates, the material hardens and a neat seam is formed at the junction.

Glue happens three types:

- Type A. The most liquid, therefore it is used for small joints and thin coatings. It is indispensable for laying linoleum with a pattern, but it can only be used for cloth with a flat edge.

- Type C. Much thicker and more durable. It is used both for laying new linoleum and for repairing old coatings. It can be used to connect gaps up to 4 mm wide.

- Type T... It requires some professional skills, therefore it is used less often than others and mainly for welding PVC coatings.

For work you will need a long ruler, double-sided tape and a construction knife.

Step-by-step instruction

- Thoroughly clean the surface from debris and dust.

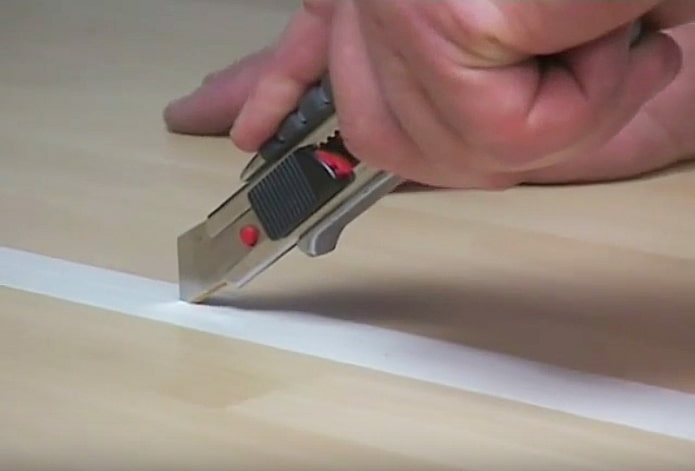

- Lay the sheets of linoleum with an overlap, draw a straight line and cut both pieces along it with a construction knife. This will allow the edges to join perfectly when welding.

- Fix the bonding area with double-sided tape.

- Inject adhesive along the entire length of the joint.

Small life hack: so that the glue does not damage the front of the coating, glue it along the connection line with masking tape and make a slot in order to pour the composition. The tape can be removed 10-20 minutes after you have applied all the adhesive.

This type of welding suitable for linoleum on any substrate - both foam and felt. For laying a covering with an area of approx. 20 sq. M. You will need one 100 ml tube of glue, so cold welding is also an economical way.

Advicethat will help you achieve an excellent result:

- In order to make even edges, you will need an overlap with a width of about 6 cm. Remember this in order to correctly calculate the amount of linoleum to buy.

- Use a needle-shaped tip when injecting the glue into the joints so that you can do it as carefully as possible.

- If the glue gets on the front of the linoleum, wait until it dries, so it will be easier to remove it.

- Any glue (especially type T) is very toxic, so do not forget about a respirator and gloves. Read the instructions carefully and ventilate the area in which you are working.

Hot welding

In this way, commercial and semi-commercial linoleum is laid, especially if it is planned to do this on a large area. During hot welding, the coating is exposed to a very high (up to 400 ° C) temperature, which ordinary household linoleum simply cannot withstand.

Sometimes hot welding is used to create decorative patterns and appliqués. This is not a complicated technology, but it requires professional knowledge and special equipment.

For hot welding method will need:

- construction vacuum cleaner;

- hair dryer gun complete with welding nozzles;

- welding cord (polymer tape);

- cutter;

- construction and month-shaped knife;

- Double-sided tape;

Important! First you need to lay and glue the linoleum to the floor and wait 24 hours. Only then, when the glue layer dries up and the linoleum finally shrinks, can the joints be welded. Otherwise, there is a high probability that the seam will deform and gaps will appear on it.

Step-by-step instruction

- As with cold welding, secure the edges of the sheets to the base using double-sided tape.

- Use a cutter to cut a groove about 3 mm wide at the junction of the linoleum, in the shape of a letter V.

- Sand the edges of the groove with sandpaper.

- Clean the joint thoroughly with a vacuum cleaner.

- The next step - work with a hairdryer. Insert the polymer cord into a suitable nozzle to heat it up as it passes through the hair dryer. The polymer and the edges of the linoleum will melt under the influence of the high temperature, and the roller will firmly weld them together.

- Remove excess resin with a month knife. It is important to do this before the seams are frozen.

- Sand the joints with zero sandpaper.

In this case, the PVC cord performs the same function as the glue in cold welding. It is necessary to press it more tightly against the groove during operation in order to fill in all the irregularities.

Main condition in order to get smooth and beautiful joints, these are professional tools. It is difficult to count on a successful result if you use a regular knife to cut the groove for the cord. Get a professional router bit that makes an even groove that is equal in width and depth. Do not try to use a regular soldering iron instead of a hair dryer - such a coating will not be beautiful and durable.

Another hot welding method - using a polymer tape. For him, you will need a special apparatus that works on the principle of an iron. The tape performs a protective function, it must be applied to the joint and driven along it with this "iron" until the upper part of the edges of the linoleum melts. Welding is ready, tape can be removed.

Double-sided tape

The easiest and cheapest way join the seam of linoleum, which does not require anything except tape and a pair of hands. In fact, this is just the first step in cold and hot welding. A strip of scotch tape is fixed on the floor and the butt joint is joined by the edges of the linoleum on its reverse side, gradually advancing to the very end.

Despite its speed and simple implementation, this method is only suitable as a temporary option. With the help of scotch tape, you will not be able to make the joints completely invisible, such a fixation is not reliable and will not last long. You can slightly increase the service life by pre-priming the surface.

Overhead nut

It is usually used at the junction of rooms. If in different rooms you have to glue two different types of linoleum and you need to mask the joints, you can attach sills to the borders of the linoleum.

This is the easiest way to solve the problem of joints., because there is no need for even edges, they will still not be visible.

The gates are indispensable if the task is to dock linoleum with another floor covering, for example, tiles or laminate.

Installation simple:

- Cut the nut to the required length with a jigsaw

- Fix it well on the floor with self-tapping screws.

Although this method of docking is durable, it must be understood that the sill protrudes 1-2 millimeters above the floor surface. Therefore, there is a chance that you will stumble when walking.

Another drawback of such a connection is the poor color range. There is no guarantee that you will find the threshold exactly in the color of the linoleum, but you can beat this by choosing a contrast threshold. For example, the color of the grout of a tile or door frame.

When choosing the most suitable way of gluing linoleum joints, consider factors such as the class of the floor covering, its thickness and color. Remember that hot welding is not suitable for household linoleum. Find quality consumables and the right tools, follow safety precautions - and you are assured of success.

10 practical tips for arranging a small kitchen in the country

10 practical tips for arranging a small kitchen in the country

12 simple ideas for a small garden that will make it visually spacious

12 simple ideas for a small garden that will make it visually spacious

What is better not to do it yourself during the repair?

What is better not to do it yourself during the repair? Bloated linoleum: how to fix it without disassembly

Bloated linoleum: how to fix it without disassembly The worst decisions in apartment renovation

The worst decisions in apartment renovation  Installation of ceiling tiles: choice of materials, preparation, order of work

Installation of ceiling tiles: choice of materials, preparation, order of work How to glue a ceiling plinth to a stretch ceiling?

How to glue a ceiling plinth to a stretch ceiling? Ceiling plinth for stretch ceiling: types, recommendations for selection

Ceiling plinth for stretch ceiling: types, recommendations for selection