Types of structures

Choosing a sound insulation method ceilings in the apartment depends not only on the thickness of the floors in the house, but also on the height and other features of the ceiling. Distinguish between frame and frameless method.

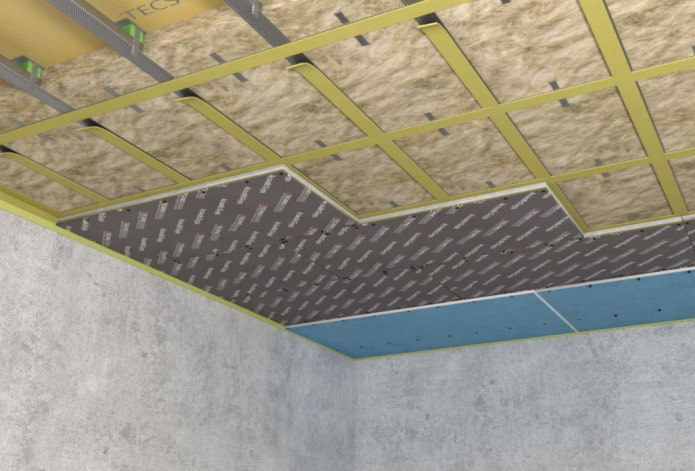

Wireframe

The thickness of the structure reaches at least 7-10 cm... A frame made of metal profiles is attached to the ceiling with the help of suspensions, less often - a wooden ceiling lathing is performed. Sound-insulating and sound-absorbing materials are placed between the frame elements. Design sheathed with plasterboard.

The main dignity frame sound insulation:

- Due to vibration suspension, the structure helps to protect residents not only from air (conversations, music), but also from a significant part of shock noises from above (stamping, falling objects).

- It allows you to combine several types of insulation materials of different thicknesses and densities. This provides the highest noise protection.

- Wiring is easily mounted in the frame profiles.

Wireframe technology use:

- in houses with a ceiling height of at least 2.7 meters;

- with significant differences in height between floor slabs;

- when installing a mounted or tiered ceiling.

However, this type of noise protection not suitable for installation in houses with weakened, crumbling floors, as well as in apartments with low ceilings.

Frameless

Depending on the materials used sound insulation thickness can be from 15 mm to 85 mm... Sound insulation is attached directly to the ceiling surface using disc dowels and glue. Drywall can be installed on top of it or stretch ceiling.

TO advantages frameless sound insulation can be attributed to:

- a thin layer of noise insulation;

- the ability to eliminate the "drum effect" that appears when installing a stretch ceiling.

Frameless soundproofing fits:

- for apartments with low ceilings;

- for installation on weakened interfloor slabs that are not able to withstand the weight of the frame structure (subject to preliminary preparation and strengthening of the floor).

Limitation for frameless soundproofing of the ceiling in the apartment, there are significant irregularities in the ceiling - they will interfere with the installation of hard plates. In this case, the surface must be leveled. Soft roll materials and membranes are less dependent on height differences. They can repeat the geometry of the interfloor overlap, and the stretch canvas will set the overall flat plane of the ceiling.

The main disadvantage The thinnest frameless structures from 15 to 30 mm are characterized by low impact noise absorption capacity. This requires a fibrous sound-absorbing material with a thickness of at least 40 mm.

What materials are used?

Building materials for noise insulation can be divided into two main types:

- Sound absorbing - dampen sound vibrations in their structure, without letting them out. Most often, according to their characteristics, these are fibrous semi-soft bases.

- Soundproof - reflect the sound wave and redirect it in the opposite direction. They have a dense surface and a high mass.

A combination of both types, where the outside is a sound-insulating solid element, and gives the best effect in blocking noise from the neighbors upstairs.

Mineral or stone wool

Most popular inexpensive material for noise insulation of the ceiling, available in the form of slabs of various sizes. Acoustic wool thickness - from 27 mm. It consists of randomly spaced thin fibers and internal air cells.

Is an excellent sound absorber for airborne and impact noise... Acoustic mineral wool boards are actively used in frame systems in combination with sheets of gypsum fiber board and gypsum board. In frameless ones, they are attached directly to the ceiling using disc dowels ("fungi").

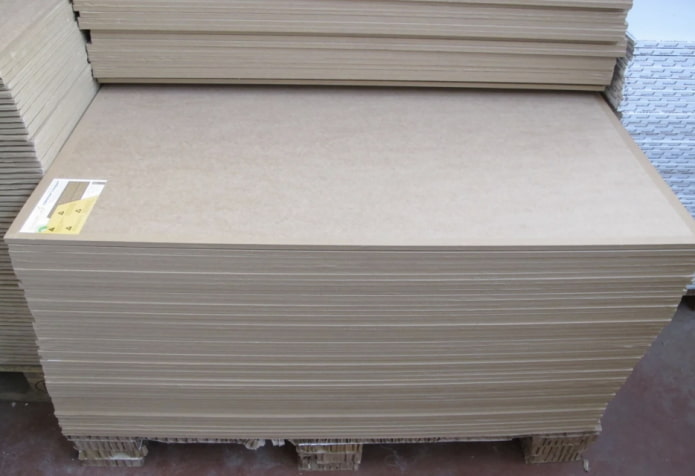

Sandwich panels ZIPS (and their analogues)

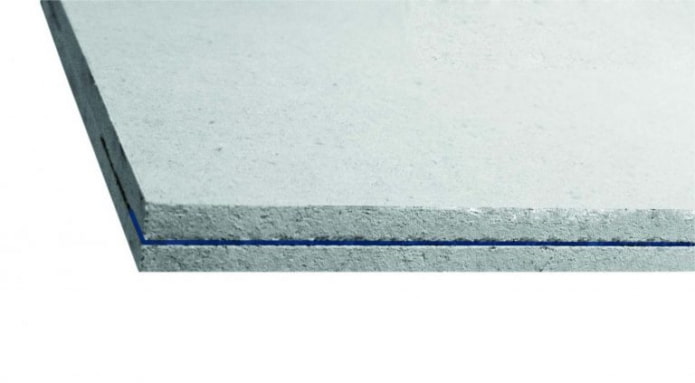

Are considered one of the most effective solutions in terms of thickness / result ratio... When installed correctly, they can reduce noise by up to 80%. They consist of a dense sheet of gypsum fiber, combined with a loose porous fiberglass. Minimum sandwich thickness from 40 mm.

The panels are designed for frameless soundproofing of the ceiling and are attached directly to concrete floors. Due to the presence of flexible support-vibration isolators on the ZIPS panel, the degree of sound insulation increases. The ZIPS-Z4 slab can be used on uneven ceilings with drops of up to 50 mm without prior leveling the surface.

Sonoplat fibreboards

Heavy panels form a rigid frame, inside of which honeycombs with finely dispersed quartz sand are formed. The filler absorbs noise, and the hard surface has sound insulating properties.

Allows you to combat shock and airborne noise... Suitable for any ceiling sound insulation systems. When installing, it is important to consider significant slab weight.

Aluminosilicate fiber MaxForte-SoundPRO

Refers to new generation materials... It is a 12 mm thick roll-up sound-absorbing material with a fibrous structure. Easy to cut, flexible.

- IN frameless structures can be used for soundproofing ceilings with complex relief and height differences.

- IN frame - acts as a damping layer between the battens and the concrete of the ceiling.

The manufacturer claims to reduce noise when using aluminosilicate fiber by 3-4 times.

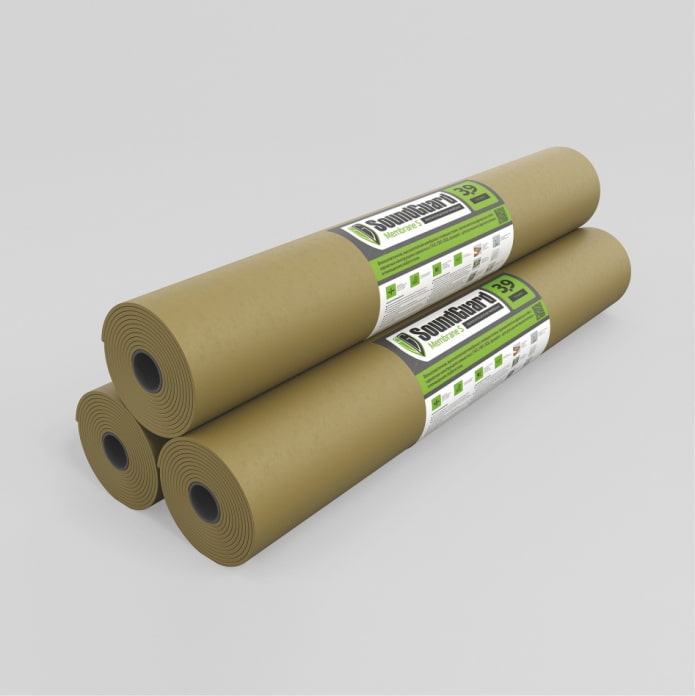

Soundproof membranes

This is a class thin roll elastic materials... The SoundGuard Membrane is up to 4mm thick, the Tecsound is 1.4 to 2.6mm thick. Manufactured from synthetic polymers with mineral fillers.

Differ solid weight and high density, which allows you to trap sound waves in the structure of the canvas. With frameless installation, they are glued directly to the ceiling or on the gypsum board, and then attached to the ceiling. With the frame method of noise insulation of the ceiling, the second option is used.

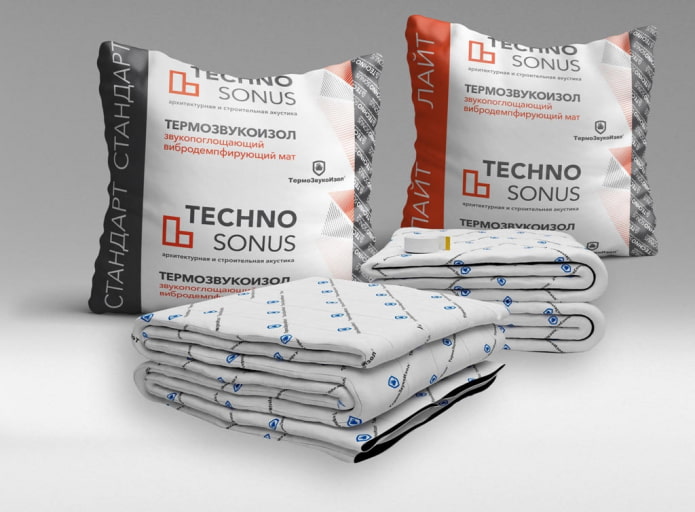

ThermoZukoIzol (TZI)

It is a fabric with a thickness of 9 to 14 mm made of needle-punched fiberglass, sealed in spunbond. This roll material often used in an apartment under a stretch ceiling and helps to resolve the issue of the appearance of the "drum effect".

Soundproof triplex Soundline-dB

According to the manufacturing technology, it is sheets of gypsum fiber fastened together with the help of an elastic sealant. Serves for cladding frame structures.

In terms of sound insulation, it replaces two layers of drywall, but at the same time it wins in thickness. The triplex is only 16.5 mm, and the GCR + GCR layer is 25 mm. Soundline can be used for external cladding of frameless ceilings. It also serves as the basis for finishing materials.

Device technology

When choosing a ceiling soundproofing option, consider key rule: in the sound-proof "pie" layers of light sound-absorbing materials (mineral wool plates, membranes) with solid sound-reflecting elements (gypsum fiber board, acoustic triplex) should alternate.Otherwise, the effectiveness of the soundproofing structure will be jeopardized.

Also, an essential role is played by the presence of an air gap between the layers of the suspended ceiling and the absence of sound bridges. The tightness of the structure is achieved by using vibration dampers, damping materials and fillers.

Tools and materials

For installation work false ceiling Prepare the following tools and supplies with your own hands.

Sound insulating materials - are selected depending on the method of sound insulation.

- For frameless systems use spare parts panels, noise-absorbing plates, roll sound insulation. The finishing layer can be used with gypsum board.

- IN frame systems are most often used acoustic mineral wool, drywall sheets.

Materials for mounting the frame:

- Aluminum profile for lathing... For installation along the perimeter of the room, prepare a guide profile (NP), for the central part of the frame - ceiling (PP).

- Vibration suspensions for fixing the profile lathing of the frame to the ceiling. A combination of standard suspensions with vibration pads is possible. Direct suspensions allow 15-135 mm to be removed from the profile from the ceiling (standard suspension bracket). If you want to lower the frame lower, choose an anchor (wire, on a traction) suspension.

- Damper or sealing tape - for mounting the guide profile to the wall.

Measuring instruments:

- laser or water level;

- tape measure, ruler.

Installation tools:

- puncher;

- construction knife for cutting drywall, soundproofing boards, roll soundproofing;

- scissors for metal or a grinder for cutting a profile, a spatula for finishing joints of gypsum boards - with frame soundproofing.

Consumables:

- self-tapping screws for metal (LB, "bugs") for connecting profiles;

- self-tapping screws with a conical head for fastening drywall;

- for frameless systems - glue, disc dowels ("fungi");

- vibration-insulating sealant.

Be careful when working with materials containing mineral fibers (acoustic mineral boards, ZIPS). When installing them, it is necessary to protect the respiratory organs with a respirator.

Step-by-step instruction

Before proceeding with the installation of the false ceiling, check the bearing capacity of the floor slabs... The quality of sound insulation largely depends on the condition of the ceiling.

Ceiling preparation:

- Remove loose paint, loose pieces of plaster, seal the cracks with sealant.

- If there is a through hole at the heating riser, fill it with tow, glass wool and plaster. Do not use polyurethane foam for insulation - this will not give a soundproofing effect and will only increase vibration. Moreover, the foam will fix the pipe in the ceiling (the riser should "walk" with linear expansion).

- Treat the overlap with an antifungal agent if necessary.

Further, the installation technology will depend on the method you choose. noise insulation of the ceiling and the soundproofing materials used in this case.

Installation of frame noise insulation:

- Using a level, mark the installation locations of the profile along the perimeter of the walls. The distance from the ceiling is determined taking into account the thickness of the soundproofing cake.

- Mark out the fastening of the frame on the ceiling. The distance between the profiles is usually 400-600 mm. Mark the places for the installation of vibro suspensions, their number depends on the load on the frame.

- Cut the profiles. The length of the ceiling profile should be 10 mm less than the width of the room.

- Glue the guide profiles (NP) with a damping vibration-damping tape in order to exclude rigid contact of the metal with the concrete of the wall. Fasten them along the markings on the wall.

- Install the vibration suspension, fix the ceiling profiles (PP) in each of them with four self-tapping screws. In the process of work, check with a level that the fastening is correct.... The ends of the ceiling profiles should go into the guide profile.

- Fill the frame with sound-insulating material - above the profiles at the ceiling or in the space between them. Additionally secure the laid material by bending the hanging edges of the hangers up. In the places where the wires are output, cut the mineral wool crosswise and pull the wires out.

- Close the ceiling with 10 mm GVL sheets using self-tapping screws with an attachment pitch of 150 mm. Fill the gaps with vibration sealant.

- The next layer is the installation of gypsum board 12.5 mm apart with the seams of the sheets of the first layer. The combination of gypsum fiber and drywall can be replaced with one layer of Soundline-dB soundproofing laminate.

- Putty the gaps between the sheets.

Installation of frameless noise insulation of the ceiling:

- Level the plane of the ceiling with plaster, prime the surface to remove dust.

- Start laying the soundproofing from the outer wall, while the materials are tightly fitted to each other at the joints. Clearances will reduce all work to zero result.

- When installing roll materials, apply adhesive to the ceiling. It will be more convenient to do this with an aerosol adhesive. Start rolling the roll immediately, pressing the material firmly against the ceiling. The edges of thin canvases are overlapped... The acoustic membranes are then carefully trimmed to form an even joint. The second way is to glue the membrane onto a drywall sheet and install the resulting panels.

- When installing sound insulation boards and sandwich panels, apply a thin layer of adhesive to the material using a notched trowel. Press the slab firmly against the ceiling, pay special attention to fixing the edges... ZIPS panels do not need preliminary gluing.

- After the adhesive has dried (after 3-6 hours), additionally fix the materials to the ceiling using disc dowels. The deepening of hardware into the ceiling should be at least 50-60 mm. The number of fasteners depends on the size of the material, but at least 5 pieces per element (in the corners and in the middle).

- If fiber boards were used as an insulating material under the stretch ceiling, they must be covered with gypsum board or vapor barrier material. Glue the joints with construction tape... This will prevent the fibers from falling onto the fabric and falling into the light slots.

So, when choosing the type of sound insulation during the repair, start from the features of the interfloor floors in the apartment. For the best effect, combine sound absorbing and sound insulating materials. A competently mounted frame or frameless construction will fully protect you from any kind of sounds from neighbors above.

10 practical tips for arranging a small kitchen in the country

10 practical tips for arranging a small kitchen in the country

12 simple ideas for a small garden that will make it visually spacious

12 simple ideas for a small garden that will make it visually spacious

What is better not to do it yourself during the repair?

What is better not to do it yourself during the repair? Bloated linoleum: how to fix it without disassembly

Bloated linoleum: how to fix it without disassembly The worst decisions in apartment renovation

The worst decisions in apartment renovation  Installation of ceiling tiles: choice of materials, preparation, order of work

Installation of ceiling tiles: choice of materials, preparation, order of work How to glue a ceiling plinth to a stretch ceiling?

How to glue a ceiling plinth to a stretch ceiling? Ceiling plinth for stretch ceiling: types, recommendations for selection

Ceiling plinth for stretch ceiling: types, recommendations for selection