What materials and tools will you need?

The installation of plastic panels begins long before construction works. The first step is to purchase all the materials:

- Directly the PVC panels themselves. To ensure that all elements match in color, choose packages from the same batch. Plastic panels are in the form of lamellas (25-30 cm wide, 2.5-3 m long), plates or sheets, as well as imitating lining (about 10 centimeters wide).

Colors, patterns and shapes are matched to the interior. They also differ in the number of stiffening ribs - models with a minimum margin of safety and low thickness are suitable as plastic panels for the ceiling. For wall cladding, a tougher plastic is required.

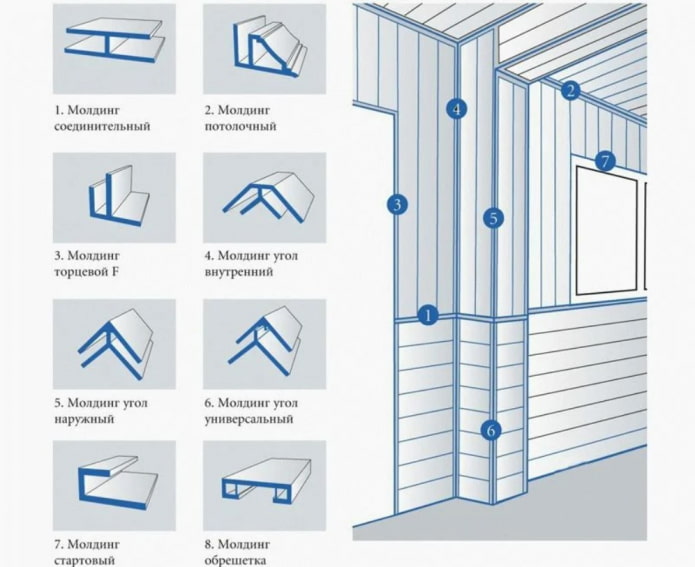

- Additional elements. Finishing materials such as internal and external corners, plugs, ceiling skirting boards and docking profiles allow you to install plastic panels more accurately and achieve the most neat result.

- Bars. If the frame method of fastening is chosen, you will need wooden bars of a small section (20-30 mm) or a metal profile.

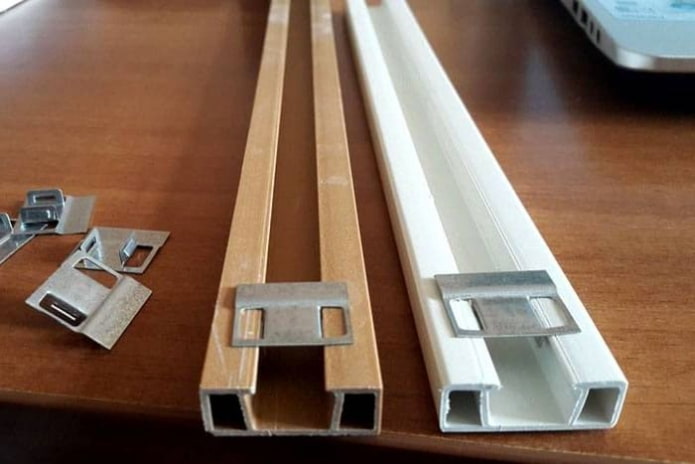

- Mounting plates + clamps or clips. The modern option for installing PVC panels is more expensive than the usual one on timber or glue, but more practical. Assembling a structure with a complete assembly kit is a matter of several hours of work.

Important! 3 and 4 points are optional, depending on the method of attaching the plastic trim.

For the installation of plastic panels also tools needed:

- Plumb line or building level... The laser, which is used by professionals, is more convenient and more accurate than the bubble one.

- Hacksaw for metal, wood or a sharp stationery knife. Depending on what is more convenient to cut PVC panels.

- Scissors... Convenient for trimming corners, plugs.

- Roulette and ruler.

- Pencil or marker.

- Ladder (if necessary).

Depending on the chosen technology, by which it is planned to fix the plastic panels, come in handy:

- Jigsaw or saw.

- Perforator (impact drill), hammer and dowels.

- Fasteners (clamps, self-tapping screws with a screwdriver, staples + stapler) when assembling panels on a crate.

- A gun for applying a sealant or glue, the silicone sealant itself or liquid nails if the plastic panels are mounted with an adhesive method.

Preparation of the base

A carefully prepared surface is the key to a high-quality result, long-term service wall decoration or ceiling. Some people believe that if the lamellas are installed on the frame, it is not necessary to remove the old finish and somehow prepare the walls. But this is not the case! All the more so if PVC panels will be located in the bathroom or in the kitchen.

Important! Whichever method you intend to fix the panels, do not skip the preparatory stage.

- Dismantling the old coating. Any wallpaper, peeling paint needs to be removed.

- Cleaning. Thoroughly clean concrete, tiles or strong paint from dirt and dust.

- Primer. To protect surfaces from mold, apply fungicidal primer around the entire perimeter with a roller or brush.

Advice! If the adhesive method is chosen for installation on a painted wall, for better adhesion of the silicone to the wall, make small notches along the entire plane.

Installation methods

Installation of plastic panels is done in different ways. Variants can be divided into 3 main groups:

Frame

Fastening to steel or wooden lathing has a row advantages:

- does not require a perfectly flat base,

- allows you to build even corners (important for installing furniture or plumbing),

- leaves free space for communication.

Of cons - reducing the area of the room (critical in small bathrooms or bathrooms), the possibility of mold due to poor air circulation, additional costs of time and money for assembling the frame. The plastic panels themselves are attached to the crate with self-tapping screws, staples or clamps.

Glue

With the help of liquid nails or sealant, PVC panels are glued to any substrate - be it plaster, paint or tile. But for the result to be successful, the walls must be as even as possible - otherwise the finish will simply overtake the irregularities and emphasize them even more.

Experts do not recommend this method, citing its unreliability, however, everyone who has tried the method from personal experience is ready to argue that the lamellas are literally glued tightly and hold perfectly even without making holes.

Mounting plate

The procedure is similar to assembling the frame, only simpler:

- 2-4 special strips are fixed perpendicular to the wall (horizontally);

- staples are inserted into the grooves, to which the first panel is attached;

- then it remains to cut the PVC panels to the desired size and substitute them to each other, from time to time securing them with staples.

How to fix panels to walls?

To carry out fastening work with your own hands, you must clearly follow the procedure described in the instructions.

Important! Before installing the panels, allow time for them to adapt to the temperature and humidity of the room to be finished. For this, the material is left for 12-48 hours in the room - the more the storage and operation temperatures differ, the longer it will take.

Step-by-step instruction

After careful preparation of the walls and a complete set of materials and tools, we begin directly the installation work. Let's take a look first adhesive finishing with PVC panels, perhaps the fastest installation method.

Advice! Plastic sticks well with liquid nails, but for a wet area (for example, a bathroom) it is better to take a transparent sealant.

- Markup. Take a level (preferably a laser), pencil and ruler. Mark a straight horizontal or vertical line to which the edge will be applied in the future.

- Starting point. Measure the height from floor to ceiling, cut the corners to the desired length and apply glue. Press down firmly, set on both sides of the first wall, let it grab. To hide the edges near window and door openings, use U-shaped plugs instead of corners.

- Finishing. Transfer the wall size to the first PVC panel, cut. Apply a few dots of glue, paste in place, align with the drawn line or level. The rest of the slats are fixed in the same way - check the level and align the PVC panel from time to time.

Important! If the first element does not rest on the floor, but starts from the middle of the wall, let it dry well before installing the rest. Rushing can lead to serious errors and geometry corruption.

The top and bottom of the structure are covered with starting profiles for PVC panels or special skirting boards.

Advice! If there is a protective film on the slats, do not remove it until the finishing work is completed: it will keep the surface intact, help to avoid scratches, and also simplify further maintenance.

Video for beginners

We decided to try frame method? See a step-by-step guide on how to install PVC lamellas on wooden battens without using corners:

Great modern method of fastening to plastic guides:

Ceiling mounting features

For perpendicular fastening, choose the frame method. Inside the box, communications for lighting and ventilation will be hidden, which will allow achieving the maximum final effect from the outside.

Step-by-step instruction

There are practically no significant differences between wall and ceiling decoration:

- Markup. Mark a clear line along the outline of the room at one level. Use a precision instrument rather than measure an equal distance from the ceiling - the latter may be crooked.

- Assembling the frame. Start by installing the contour strips (it is better to choose a metal profile for the gypsum board - a bubble level on a magnet is conveniently attached to it), then insert the crossbars, fixing them on the sides to the guides and the ceiling.

- Installation of PVC. Starting from one corner, moving across the guides, fasten the panels to the profile using self-tapping screws. The edges can be closed with plugs immediately or the skirting board can be installed after finishing work on the ceiling.

Video for beginners

For step-by-step finishing of the ceiling with little secrets from the master, see the video instructions:

Although the level of complexity of working with PVC is minimal, all manipulations also require skill and a "full hand". Always take the material with a margin to have a free lamella to replace the damaged one.

10 practical tips for arranging a small kitchen in the country

10 practical tips for arranging a small kitchen in the country

12 simple ideas for a small garden that will make it visually spacious

12 simple ideas for a small garden that will make it visually spacious

What is better not to do it yourself during the repair?

What is better not to do it yourself during the repair? Bloated linoleum: how to fix it without disassembly

Bloated linoleum: how to fix it without disassembly The worst decisions in apartment renovation

The worst decisions in apartment renovation  Installation of ceiling tiles: choice of materials, preparation, order of work

Installation of ceiling tiles: choice of materials, preparation, order of work How to glue a ceiling plinth to a stretch ceiling?

How to glue a ceiling plinth to a stretch ceiling? Ceiling plinth for stretch ceiling: types, recommendations for selection

Ceiling plinth for stretch ceiling: types, recommendations for selection