Why do you need a backing?

The use of a laminate underlay is due to several factors:

- Shock absorbing properties... A spacer between the decorative flooring and the subfloor will reduce the breaking pressure on the bottom layer of the laminate when walking.

- Soundproofing... If laminate flooring is laid on concrete without bedding, it will emit a dull sound from footsteps or impacts.

- Thermal insulation. Laminate, Unlike tiles - not so cold. But if it is laid on a bare concrete floor, it will still be cold to walk, not to mention sitting or lying on the floor. A laminate underlay will solve the temperature problem.

- Waterproofing... Not all types of substrates provide 100% protection against water, moreover, there are gaps between the sheets - therefore, this cannot be called a full-fledged waterproofing. But the gasket protects the lower paper layer from swelling due to condensation.

- Smoothing uneven floors... Before installing the laminate, the base is carefully prepared, but if the floor is already even, but has slight irregularities (up to 2 mm), the lining will smooth them out.

What types are there?

Laminate substrates differ in material of manufacture, thickness and functionality. Let's look at the advantages and disadvantages of the main types.

Cork backing

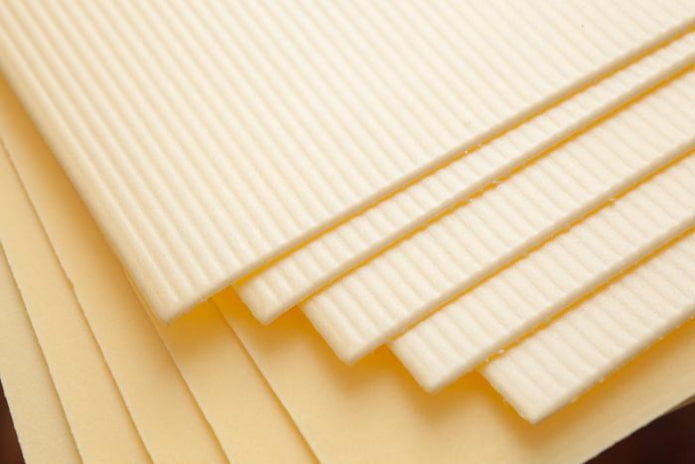

Cork backing is an environmentally friendly material made from the bark of cork. Cork chips are pressed into sheets of different thicknesses without the use of glue - there is already a resinous secret in the wood, which firmly glues the elements together. It is produced both in rolls and in separate sheets.

If the cork backing is made without the addition of additional components, it is hypoallergenic and suitable for installation in children's rooms, bedrooms and any other premises.

To make the substrate under the laminate more durable and add new properties to it, manufacturers mix the crumb with bitumen or rubber.

The material is no longer so natural, but it easily withstands the effects of moisture and constant mechanical stress. Improved cork for aggressive environments, suitable for corridors, kitchens.

When it comes to natural material, fear of moisture is one of its disadvantages. The second disadvantage is due to the dependence on temperature and humidity: natural wood can shrink or expand with changes in indicators. Therefore, floor heating is prohibited.

And the last nuance is the price. Any natural wood is more expensive than synthetic materials, cork backing is no exception.

Foamed polyethylene

In fact, it is a foil base and a polyethylene film treated with a special foaming agent. Tiny bubbles are created in the structure, which give plumpness to the material.

The main advantage of this roll-up laminate underlay is the price. The average cost per square meter is ~ 20 rubles. In addition, it is light - so it will not be difficult to bring it into the apartment.

Another plus of the polymer is moisture resistance.Like any polyethylene, it is not afraid of water and moisture. In addition, with prolonged exposure, mold and mildew will not appear on the surface.

The main disadvantages of foamed polyethylene are considered to be its low load resistance and strong shrinkage. Bubbles in the structure burst over time and instead of covered 3 mm after 1-2 years of use (or even less) the gasket barely reaches 1 mm. This negatively affects the decorative flooring - the lamellas move apart, the locks begin to creak, and the service life is reduced.

The second drawback is the build-up of static electricity. It attracts dust to the floor like a magnet - you will have to clean up more often, especially if you chose a dark surface.

Expanded polystyrene foam

Another name - extruded polystyrene - means that the material is obtained as a result of extrusion (foaming) of granules. Expanded polystyrene is denser than polyethylene, it is produced mainly in sheet form (separate or "accordion"). Less commonly found in rolls.

Although the structure contains the same gas bubbles, the material itself has a large margin of density and strength. And, accordingly, durability - the service life is approximately equal to the lifespan of a high-quality laminate.

Due to the preservation of its shape and properties in almost any temperature conditions, expanded polystyrene is laid even in unheated rooms. The structure itself does not conduct much heat, so the floor will remain warm.

The next advantage will appeal not only to you, but also to the neighbors below: polystyrene laminate substrates have increased sound insulation, absorb up to 70% of noise.

Let's move on to the cons:

- low leveling ability (the base should be carefully prepared);

- environmental insecurity (may emit corrosive substances);

- highly flammable.

Coniferous substrate

Although it is green, it is not made from spruce needles, but from coniferous wood. High-density plates act as a shock absorber, they are of different thicknesses, and can neutralize differences in height.

The material is "living" - it allows air to pass through and contributes to the establishment of a microclimate in the room - it picks up excess moisture and returns it when the air dries.

The coniferous substrate has high rigidity, practically does not deform, and serves for many years. But the advantages are overshadowed by the only drawback: high cost. While value for money is warranted, some may find the cost unreasonable.

Combined underlay

Progress does not stand still, and thanks to new technologies, composite materials have appeared on the market for laminate substrates. The most popular are Parkolag from the Swedish company Icopal and Tuplex from the Finnish manufacturer of the same name.

The advantage of these synthetic pads in the combination of polyethylene and polystyrene: the manufacturing process creates a "layer cake" of various components, which as a result surpasses pure materials in quality and durability.

A duplex, for example, consists of 3 layers:

- upper - perforated membrane;

- medium - expanded polystyrene granules;

- bottom - dense polyethylene.

Laying the combined types is simple: they are sold in rolls, are lightweight and fit perfectly on any substrate.

How to choose a substrate?

It is logical to assume what should be the damper for the laminate and parquet boards, it is better to ask the manufacturer of the laminate for a specific brand and model.

In fact, it is - most companies indicate on their products what is better to use as a substrate. But in addition to the technical characteristics and the class of lamellas, the features of the original flooring should also be taken into account.

| Base type | Type of underlay for laminate |

|---|---|

| Concrete base | Expanded polystyrene or polyethylene, or any other with a preliminary waterproofing film. |

| Wooden floor | Breathable pads (cork, coniferous) will exclude decay and deterioration of the base. |

| Warm floor | Expanded polystyrene, polyethylene, perforated cork without foil. Or options with special marks "Suitable for underfloor heating". |

| Tile | Hard cork or coniferous sheets. |

When choosing a substrate for a laminate on a screed or any other base, you should consider:

- Substrate thickness... It should not be more than 3 mm - this rule applies to any type. Thicker linings tend to sag, which negatively affects the quality of the installed floor. For rigid and rigid sheet materials, a thickness of 2 mm is sufficient.

- Durability... The cheapest polyethylene gaskets will hardly affect the price of repairs, but after a while gaps may form at the joints and the laminate will have to be put in a new one.

- Convenience of transportation and handling... This factor does not affect the operation, but if you live on the 9th floor, and the sheets or roll will not enter the elevator, there will be little pleasant. There is a large selection in hardware stores - look for what suits you by all criteria.

How to stack correctly?

The quality of laying the parquet board itself and the duration of its service depend on how well the substrate under the laminate is laid.

Step-by-step instruction

The first step is to check the base: the concrete floor from the developer is often poured out of level, has drops, various irregularities. If the concrete screed is flat but old, examine it for cracks and voids.

It is best to pour it on a level before placing the substrate under the laminate on the concrete floor - this is the only way to be sure that the coating will be durable.

Important! You should not try to level the uneven base with a thick lining - over time, in the places of the grooves, it will sag and the problem will come out.

The next step is cleaning. It is better to use substrates on clean surfaces - no dust, dirt. Grains of sand and other solid particles can cause squeaks and extraneous sounds, so it is important to get rid of them before laying.

Substrate requirements: dry, clean, even surface without cracks, voids, bumps.

Advice! While the preparatory work is being carried out, the finishing materials should be opened and allowed to adapt for 24-72 hours to the temperature and humidity of the room.

Installation tools:

- pencil or marker;

- tape measure, square;

- tape or glue (depending on the type);

- utility knife or scissors.

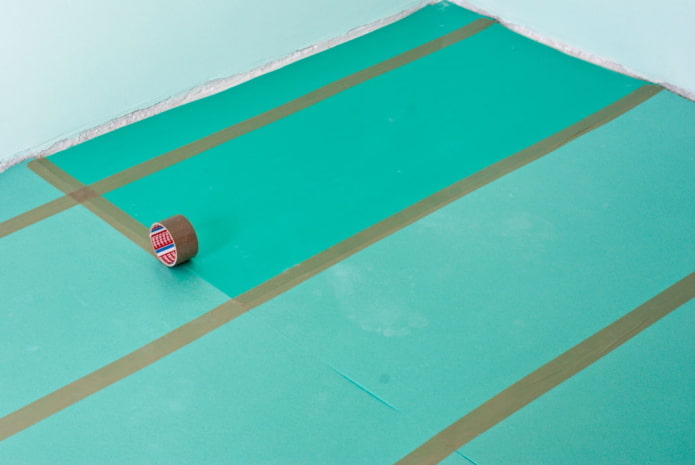

They start to lay from the inner corner and move towards the door. The sheets are recommended to be placed across the selected direction of the lamellas, but it is better to lay them diagonally - this way you will definitely avoid the coincidence of the joints of the laminate and the gasket.

Slightly backing from the walls (1-2 cm), place the first piece in the corner. Lay the next layer end-to-end (not overlapping!) To the first, connect with adhesive tape. Continue until you have covered the entire floor surface.

They also do the same with rolled materials - they put the first canvas, glue the second to it, add a third, etc.

Important! To simplify the process of laying the coating and extend its service life, both layers (outer and inner) should be wound under the door frames. To do this, remove the mounting foam from below, or cut the box to the thickness of the layers - if it reaches the subfloor.

It is advisable not to leave the substrate open, but immediately put a decorative coating on it - this way you will avoid shifting the base and getting debris under the panels.

Video

To make it easier to understand which lining option to choose, see a visual overview of all existing types:

If you are planning to install a warm floor, choose a special flooring:

Preparation in repair work is considered even more important than decorative finishing: quality, durability and beauty depend on it. Do not skimp on the substrate, choose the type that suits you best and your floors will serve you for many years!

10 practical tips for arranging a small kitchen in the country

10 practical tips for arranging a small kitchen in the country

12 simple ideas for a small garden that will make it visually spacious

12 simple ideas for a small garden that will make it visually spacious

What is better not to do it yourself during the repair?

What is better not to do it yourself during the repair? Bloated linoleum: how to fix it without disassembly

Bloated linoleum: how to fix it without disassembly The worst decisions in apartment renovation

The worst decisions in apartment renovation  Installation of ceiling tiles: choice of materials, preparation, order of work

Installation of ceiling tiles: choice of materials, preparation, order of work How to glue a ceiling plinth to a stretch ceiling?

How to glue a ceiling plinth to a stretch ceiling? Ceiling plinth for stretch ceiling: types, recommendations for selection

Ceiling plinth for stretch ceiling: types, recommendations for selection